Sharpening is correct for the tool. Yak sharpen the tool with your own hands

In the process of robots, the edges of the tools become dull, so that the machining of parts and workpieces is reduced to a decrease in the quality, the productivity of the work is reduced, as well as the wear of the tools themselves. Sharpening is correct for all the problems. The one who fixes the maystriy slid vivchita recommendations for the correct sharpening of the tool in different ways.

In order to bring the laughing edge of any tool into attachment for the other robot, it is necessary to step up.

Forming the first chamfer

The process of polishing in obrobtsіlez behind the aid of a grinding verstat or a flat stone of such a rank, to form the first chamfer (skіs pіd cutom 25 or 30 degrees). When tsomu importantly follow the singing rules.

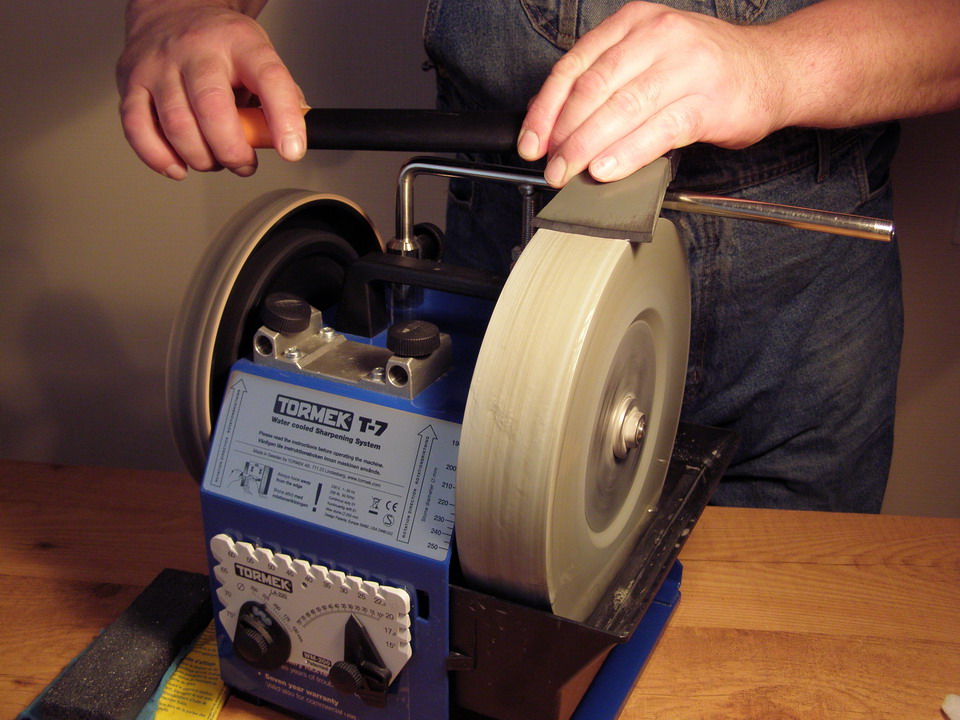

- An electric tool for sharpening will be more effective, as it is necessary to put in a lot of chives and vidcoli.

- The frequency of wrapping an abrasive cola is not guilty of changing over 2000 rpm, the granularity of the circle is vibrating in between 100-120 od.

- It is recommended to sharpen with an abrasive based on aluminum oxide, so as the stench (in the form of ancient silica) will ensure the cleanliness of the scrap metal. Besides, such cola does not overheat metal.

- When manually sharpened vikoristovuyut emery papyr or abrasive stone with grain size in between 100-320 od.

- Do not allow overheating and oxidation of the surface edge (until the metal is melted), in the process of chilling it periodically cool down, dipping it into cold water.

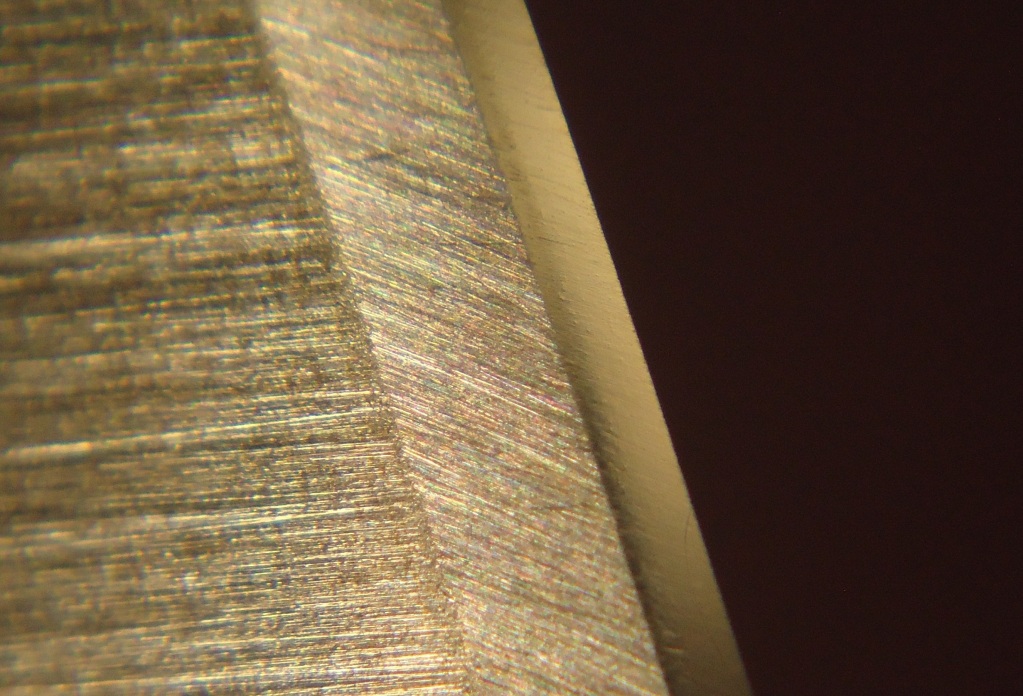

Important: the shape of the primary chamfer is to be laid down according to the sharpening method. I will manually shape a flat chamfer, and for the help of an electric tool, I will be turned away.

Rustic edge shaping

In addition, as the primary chamfer will be ready, it is necessary to bring the blade to the necessary hospitality. In the process of bringing it into view, it will happen.

- Sharpening the tool is brought to the area of the abrasive stake before the cut, reduced by 4-5 ° towards the front. The edge of the wood must be cut in such a way that you can trim the vuzka microfask.

- For sharpening vikoristovuєtsya emery papir 600-8000 od. granularity. It is important to zupiniti the process in order not to allow the deterioration of the characteristics of the working instrument.

- The effective grinding of the edge is done in two stages: with an abrasive grain of 1000-4000 odes, and then - 5000-8000 odes.

- Robimo correct shape of the ryzhuchoy edge behind the additional "vizki" - zagostryvalnoy attachment, in which tool is installed and fixed to the necessary cut. This method is suitable for high (minimum 6 mm) and wide (up to 73 mm) climbs, such as vikoristovyutsya in a plane. The roller allows you to move the blade freely, if it is installed, we will remove it with a cut-out, bridging the surface of the abrasive. In the process of robots to follow the position of the roller: the fault is not guilty of moving from the supporting surface.

It is important: the width of the micro-face is not guilty of perevischuvati 1 mm. In the process of bringing the slid regularly to overturn, at the same stage is to find the tool. In this type of vipad, you will need to re-shape the chamfer.

Emery paper for sharpening tools

For robots, emery paper 220, 320, 600, 1200 grit is used for sharpening verstati, for finishing - between 2000-4000. Finishing (polishing) is of great importance for tools on wood: the gostra edge is well-cut material and it is not so easy to dull. Methods of polishing the field in the offensive.

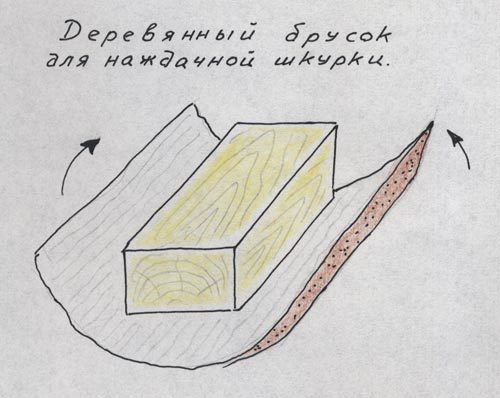

- The material is vibrated from a solid and flat surface (it can also be a piece of granite plate, tovste sklo, laminated chipboard or an extraordinary wooden block). Zruchnіshe vikoristovuvati a bar with a size of 75 × 200 mm.

- The emery paper is glued to the bar. Prepare a piece of bars with fine grain with abrasives.

- Stick to the workbench on top of the gum pad (for stiffness).

- Sharpening the tool to stand up to a cut of 25-30 ° for chamfering. With an onslaught it was possible to move the bridle of the square of the bar.

- Determine the finished lez with the number of the abrasive.

- Polishing the stylish side of the cutting tool (the area of the cutting edge is 10-12 mm wide).

Slid the nobility all the plus and minus given to the way:

- cheapness: emery paper and glue for making pre-adhesion doesn’t vimage significant vitrates;

- availability: necessary materials є in any wake-up shop;

- if you are too keen on tools, you will not be on the verstat;

- Shvidny wear of the emery paper vimagaє її periodically change.

Sharpening of tools for additional water stone

For robots, it is necessary to use abrasives of a thousand, 4000, 8000 grit in their own ordered abrasives. The technology of transferring the processing of the cutting edge behind the additional three stones.

The joy: it is possible to change vitrati, if you add a combination of stones, the sides of which may change the graininess.

The special features of the method are in the offensive:

- before grinding the abrasive, it is necessary to soak the abrasive (immersed in water for 15-20 minutes);

- in the process of robots the stone slides periodically;

- it is finished to be repaired with a grit of a stone of 1000 grit, for which it can be changed to a grain size of 4000, and then - 8000 grit.

It is important for the nobility: abrasives with a grain size of 1000 and 4000 grit can be trimmed in the water for a trivial hour, but more others can come into disrepair.

Chim of trash, and chim of garnishing method.

- The term for the service of water stones is not great. The surface of the abrasive needs to be periodically cleaned, to remove the furrows.

- It takes an hour to bring the tool to the water stone.

- Water for soaking stones is required from time to time to be mined, so that it is difficult to find the verstat.

- In the course of the building, the robots are going to hang out in a warm environment. In the frost, the stench can zruynuvatisya.

You can learn more about the process of sharpening the tool on a water stone by looking at the video.

Sharpening of tools with diamond inserts

Diamond plates are used for sharpening the cutting edges of tools, made from hard steel grades. Practical zasosuvanny hand plates are double-sided, up to 190-200 mm with a grain size of 600/1200 grit. Follow the singing rules with them.

- A flat chamfer is to be molded behind the additional plate with a grain size of 600 grit, finished with an abrasive of 1200 grit.

- The plate is wet with water.

- It’s easy to sharpen up to wear to abrasive before cutting and to move the bridged area. Chiselled particles of metal are bought up in special openings of steel pads.

It's good: the special oil is good for itself in the quality of an anticorrosive coating, but it is not effective for substitution. It is recommended to replace the oil with water (the surface of the abrasive will not be so easily bruised). Drying the diamond plates must be dried.

In the process of robots, carpentry and carpentry tools become blunt, and the robot with them becomes more effective. Pampering and the quality of the surfaces that have been crumbled by them. It is necessary to have time and to correct the storing of the rear edges.

Sharpen the yak with your hands

Sokiri with a straight climb vimagayut vitrate of strength, and the stench of triviality. To put the working tool in order, before the hour is imprisoned, it is necessary to start.

- The sphere of victorian: sokira can be a carpenter, a ribal, or can be stuck in a cleaver.

- Material, for processing what is needed for sokir (breed and variety of wood, її vologist).

- Brand of metal, zakogo vigotovaniya sokiru.

Falling aside, the shape of the edge of the lez sokiri is vibrated, which can be:

- oval (for splitting and trimming wood);

- a razor (for precise carpentry robots);

- wedge-shaped (universal type of edge for sokiri, adjoining for splitting and for painting the surface of wood).

The technology of sokiri imprisonment, how to get vicky in the booth, transferring the processing of the lez in two stages.

- Primary sharpening: form a 15 ° bevel.

- Bringing: to form a r_zhuch-edge with a cut of 25 ° (for side-by-side tools).

In the process of imprisoning the unicati:

- overheating the leza;

- substitution of zagostryuvalnoy to the instrument;

- misalignment and weak fixation of the abrasive wheel;

- vikorystannya stake with uneven wear;

- beating the shaft of the electric motor sharpener.

Nuansi we drank

If you need to stop the saw, it is necessary to reconsider the setting of the teeth. It’s necessary - to breed їх so, through one tooth, nahil їkh buvs at ізні sides. To sharpen the teeth from one side. The ryzhucha edge is guilty but is straightened into the side of the handle.

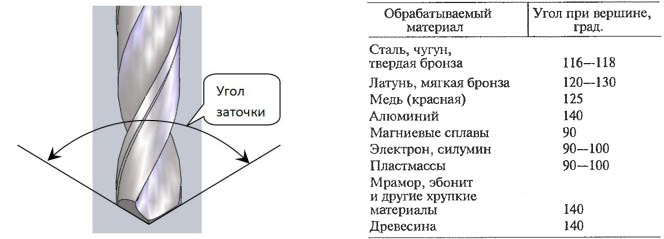

I drilled it with my own hands

Drills become blunt, as they are used for processing metal. The edge of such a drill can be changed.

The main points for which you need to beasts I respect:

- the edge is blamed in one area with abrasive stone;

- for an hour the robot slid down to press down to abrasive;

- it is necessary to stitch for the shape of the edges: the stench is guilty but the same dozhini.

There are two types of sharpening.

- Single-flat (for drilled with a diameter of up to 3 mm). It is firmly oversubstituted parallel to the working surface of the sharpening stake.

- Konichna (two-corners). Hardly go to the abrasive before the cut and go from the side to the bik. The method is suitable for drills with a diameter greater than 3 mm.

Driven by the visitor on the soft stone.

It’s good: for the zaochuvannya, I’ve done it with special attachments (verstats), so I’ll allow you to use the necessary kutom in a proper way.

Yak to sharpen a chisel and a plane

For this purpose, the robot will be quick and clear, and it will be quick with joy.

- Before sharpening an abrasive circle, or a bar, it is necessary to place it on a sprinkle of quill in the gas.

- Leso chisels or a planer can be vitrified up to 30 mins in the range of kitchen salt.

- For finishing, you can use a self-propelled shlifuvalnuy machine, as you can use an old electric shaver. For the whole replacement of knives, insert a metal plate with a glued sanding paper.

Punishments for sharpened tools

It’s an hour to spend a lot of time on the tool, to be victorious in different ways, next to one of the lowest pererakhovannyh pardons.

- It is necessary to periodically re-engage the cooling process in the water. In the first place, the overheated metal (it is possible to recognize it according to the change in color) becomes creepy. As a result, the sharpening is brought to the viconuvati anew, and the price will be carried out before the hour of wear to the tool.

- The fixes of the sharpened wood are not enough. It is important that the verstat of the building blocks on the massive, kindly reinforced bed (verstati), which is guilty of becoming unkempt for an hour, is a robot.

- The abrasive wheel is guilty of sitting on the shaft of the electric generator. It is not allowed to skew, overwhelming and uneven wear, as well as bittya of the shaft.

- It is not recommended to use a small tool on a col, as it is suitable for wide blades. Vuzki furrows on abrasives will be used to seal hard metal.

At the end - a video lesson from the carpentry tool.